- Home

- >VFD Application Guide

VFD Application Core Selection Guide

CoolBLUE® cores per horsepower and cable length

| CoolBLUE® | CBO43HP1/4-50A4 | CBO43HP1/4-50A4 | CBO68HP51-100A6 | CBO155HP101-428A12 | CBR166HP429-1631A16 | CBO326HP1632+A23 |

|---|---|---|---|---|---|---|

| Power Range (hp) | *1/4-10 | 11-50 | 51-100 | 101-428 | 429-1631 | 1632+ |

| Cable Length | # Cores | # Cores | # Cores | # Cores | # Cores | # Cores |

| 150ft/50m | 2 | 4 | 4 | 4 | 4 | 4 |

| 300ft/100m | 4 | 4 | 4 | 4 | 4 | 4 |

| 450ft/150m | 6 | 6 | 6 | 6 | 6 | 6 |

| 900ft/300m | 8 | 8 | 8 | 8 | 8 | 8 |

Note 1 – Data above is for information/guideline purposes.

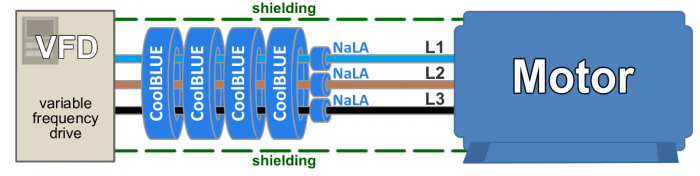

Note 2 – All cables/phases must travel through the CoolBLUE® cores. NaLA® cores are installed around each individual power cable, regardless of how many cables. Per application guide, NaLA® cores are per cable. No ground or shielding through cores!

*Note 3 – On motors up to 10hp, two turns are needed through the CoolBLUE® cores (pass cable through cores twice).

Note 4 – It is important to use the correct number and type of cores.

Note 5 – For servo and DC motors, please call CoolBLUE® Engineering.

Note 6 – Install cores on load side of drive for typical motor applications. Cores may be installed on line side of VFD as well to reduce conductive and radiated emissions back to the power grid.

Note 7 – CoolBLUE® offers brackets, and cable ties to hold cores in place. Please call CoolBLUE® Engineering for alternative methods.

NaLA® cores per horsepower and cable length

The use of NaLA® increases the reliability of these systems by further reducing the noise and peak values. These cores must be placed around each individual cable.

| NaLA® Part number | N18HP1/4-10 | N18HP11-40 | N29HP41-102 | N57HP103-428 | N75HP429-1631 | N123HP1632+ |

|---|---|---|---|---|---|---|

| Power Range (hp) | 1/4-10 | 11-40 | 41-102 | 103-428 | 429-1631 | 1632 and above |

| Cable Length | # Cores | # Cores | # Cores | # Cores | # Cores | # Cores |

| 150ft/50m | 2 | 1 | 1 | 1 | 1 | 1 |

| 300ft/100m | 3 | 2 | 2 | 2 | 2 | 2 |

| 450ft/150m | 4 | 3 | 3 | 3 | 3 | 3 |

| 900ft/300m | 5 | 4 | 4 | 4 | 4 | 4 |

Note 1 – Data above is for information/guideline purposes.

Note 2 – All cables/phases must travel through the CoolBLUE® cores. NaLA® cores are installed around each individual power cable, regardless of how many cables. Per application guide, NaLA® cores are per cable. No ground or shielding through cores!

*Note 3 – On motors up to 10hp, two turns are needed through the CoolBLUE® cores (pass cable through cores twice).

Note 4 – It is important to use the correct number and type of cores.

Note 5 – For servo and DC motors, please call CoolBLUE® Engineering.

Note 6 – Install cores on load side of drive for typical motor applications. Cores may be installed on line side of VFD as well to reduce conductive and radiated emissions back to the power grid.

Note 7 – CoolBLUE® offers brackets, and cable ties to hold cores in place. Please call CoolBLUE® Engineering for alternative methods.

* Cable length between drive and motor must be multiplied by the number of cables per phase, to calculate the total cable length to be used in above guide for CoolBLUE®. The actual length of each cable, is used in the NaLA® guide.

** For cable runs over 950ft, contact CoolBLUE® Engineering.

Contact your local CoolBLUE® Engineer for detailed information.